Thermodynamics energy measurement in air and several flue gases

On field measurements about flow rates and temperatures

Modern technologies easly grants important resources to the control and management of energy efficiency thanks to the large smart electronics diffusion.

In single machines so as complex systems, all fluid energy transformations, from generation, processing, retrieval, harvesting and distribution, can be accurate measured by continuous monitoring.

Classic primary elements employed to snapshot variables for data collection are represented by the Pitot tube averaging, our PITOBAR pattern design, joined to the resistance sensors RTD for temperature probes.

Depending on the medium fluid nature, by a differential pressure transmitter it is simple to rate its density variations as a function of the static pressure and the temperature conditions.

Running measures of main thermodynamics parameters

Computer task is to log data on continuous, parsing and updating all values setting up: internal energy, enthalpy, entropy, free energy alias Gibbs energy, work energy alias Helmholtz energy, efficiency, thermal power, and so others choosing the appropriate measurement units.

PPC_FLOWSAT_TD is a modern flow computer configured for thermodynamic applications. The calculator core is hosted in to our family of PPC_FLOWSAT_TD housing with front operator panel interface. Several input registers can be arranged to acquire the variables by proper analog/digital sensors.

An updated database, useful to the energy calculation, contains the characteristic properties of fluid media according to its condition state. The suited best algorithms allows us to optimize sensitivity and accuracy.

Different kinds of outputs, analogs or digitals, available respectively for remote reading or downloading stored data from internal memory of the computer itself.

Option cards enlarge the use of our PPC_FLOWSAT_TD as monitoring stations or stand-alone thermal energy meters/counter with site detections by GPS and by wireless connection, as web server on the Internet.

Isokinetic and isentropic flow profiling by quadratic primary elements

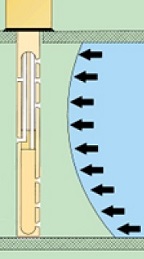

Measuring in to subsonic ranges, compressible inviscid fluids, even against medium and high temperatures, it is preferable to use a reliable primary element, which achieves high reproducibility with respect to the average velocity profile of stream in the orthogonal section to the motion direction.

In these scenarios, it is preferable to choose primary quadrat flow element such as our PITOBAR insertion probes. So that the only necessary parameter to the control volume determination, is the equivalent section's area.

This issue is simply, referring to the surfaces of known geometry, or can be derived by instrumental test calibrations.

On alternative the choice of Venturi's primary flow elements, privileges the in line mounting with our PRIOR pattern design, where applications are in ducts, channels or pipes geometrical defined, enhancing to the large variations of Reynold numbers and so as densities in different phases, for many fluids kinds, also not homogeneous.

Rated primary elements of flow

Temperatures profile

Accurate determination of any temperatures profile may be difficult using traditional temperature sensors. Especially in the presence of turbulent flows scenarios, more or less well mixed together.

Grids or sensors arrays, aligned along certain flow directions, make most affordable the temperatures monitoring, in sites near to obstacles, detours, narrowings, shut-off valves, and so on.

Posted in: Technologies and instruments evaluation